Hoek-Brown material can only be used as a failure criterion for elastic analyzes in Map3D Fault-Slip.

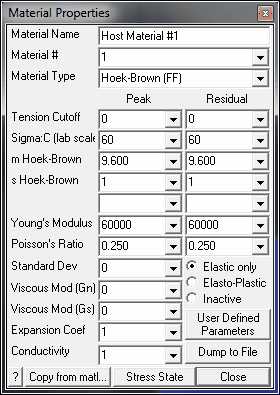

Material Name - specifies a descriptive name for the material.

Material # - specifies the material number.

•Material #1 is reserved for the host material.

•Other material numbers are used to define alternate material zones such as ore, fault gouge, backfill etc.

Material Type - specifies the material type (Mohr-Coulomb, Hoek-Brown, Drucker-Prager, Fault-Gouge, Hyperbolic-Backfill, Quadratic-Backfill, Equilibrated-Gouge, Yielding-Pillar or none).

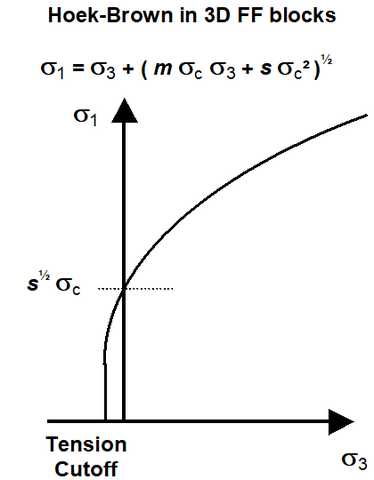

•Hoek-Brown - defines the failure envelope as a curved line.

•For 3D FF blocks the Hoek-Brown criterion defines strength in terms of principal stresses as follows:

•Tension cutoff and σc are specified in units of stress (MPa or psi).

•Only the peak values are used.

Young's Modulus and Poisson's Ratio - specify Young's (rock mass scale - deformation) Modulus in units of stress (MPa or psi).

•Only the peak values are used.

Standard Deviation - specify standard deviation in units of stress (MPa or psi).

•This parameter describes the uncertainty you have in the strength parameters.

•This parameter is only used for plotting the probability of shear failure Plot > Strength Factors > Rockmass Probability N-distribution.

Viscous Modulus (Gn and Gs) - These parameters are not used for the Hoek-Brown material.

Expansion Coefficient and Conductivity are only used in Map3D Thermal-Fluid Flow. Map3D Thermal-Fluid Flow can be used to simultaneously solve steady state heat/fluid flow coupled to the stress analysis.

Elastic only - when checked this material will respond elastically only, i.e. strength parameters will not be used.

•This can be used to define zones with different elastic properties and/or initial stress states. This could include for example stiff dykes, soft ore zones, backfill or support elements.

Elasto-Plastic - when checked this material will respond elasto-visco-plastically, i.e. the strength parameters will be used as a flow rule.

•This can be used to define zones with both different elastic properties and strength parameters.

•Note that in Map3D Fault-Slip, only DD elements (i.e. fault gouge) are permitted to respond non-linearly.

•In Map3D Non-Linear the 3D rock mass can also yield plastically.

•Yielding of Hoek-Brown materials is not supported at this time.

Inactive - when checked this material will not be used in the stress analysis and hence will not affect the predicted stresses, strains or displacements.

•This can be used to define zones with different strength parameters to be used when generating contours of strength factors.

User Defined - allows specification of user defined parameters to be used in contouring.

•Different parameters are defined for each material number.

•These parameters are used with ![]() Plot > Stress > User

Plot > Stress > User

•This can be used to define zones with different strength parameters to be used when generating contours of strength factors.

Dump to File - allows you to dump all material property data to a file for viewing in Notepad or Excel.

Copy from material - allows you to copy the material properties from one material number to another. All properties including the stress state are copied.

Stress State - specifies the initial (far field) stress state for the material.

•Most materials are inserted into blocks with the same (far field) stress state.

•Materials such as props or backfill are placed at near zero initial stresses.

Related Topics:

Drucker-Prager in 3D FF blocks